Time to Break the Plastic Wave

Over 9 million tons of plastic waste end up in the ocean every year. Over 700 species of marine animals, including endangered ones, are reported to have eaten or been entangled in plastic. Scientists think that the amount of plastic in the ocean might TRIPLE by 2050.

The plastic waste crisis in the marine ecosystem is a problem that impacts all of us and not just life below the surface. Be part of the solution and take action now. Together we can protect our planet, preserve our oceans, and provide a safe and healthy environment for humankind.

Efforts to Protect the Ocean, CJ PHACT Provides a Solution

CJ PHACT is a 100% bio-based polyester produced by fermentation.

Using CJ Bio’s innovative fermentation technology, PHACT is a 100% bio-based, marine biodegradable plastic.

PHACT is an eco-friendly material that provides a solution to address plastic waste and is capable of all modes of biodegradation including marine, soil, home, and industrial composting.

100% BIO-BASED

MARINE DEGRADABLE

TRANSPARENT

A Solution to the Pollution Crisis in the Marine Ecosystem

PHACT is our brand of Polyhydroxyalkanoates (PHA). PHAs are a family of biobased

and biodegradable polyesters made by bacterial fermentation. Based on leading-edge strain and metabolic engineering,

our biopolymer solutions offer attractive, sustainable alternatives to petrochemical-based materials. Our unique technology platform enables

PHA biobased polymers to meet a variety of performance requirements—whether you’re seeking to increase bio content,

meet a biodegradation specification, or increase durability and flexibility.

CJ Bio develops innovative, biobased polymer solutions that enhance performance and add value

for a wide range of industrial and consumer products. What sets CJ apart is world-scale biotech assets with

a world-class technology portfolio to enable circular and sustainable solution.

.png)

Innovation

PHACT PHA (Polyhydroxyalkanoate) is produced by bacterial fermentation of sugar

- PHAs are naturally occurring linear polyesters

- CJ has the unique ability to produce a wide range of polymer compositions by employing microbial engineering innovation

- Definition : PHA, Polyhydroxyalkanoate, P3HB4HB

- Chemical structure of CJ PHACT

-

3HB 100%

Crystalline PHA(cPHA) Brittle

High thermal resistance -

4HB 5~15%

Semi-crystalline PHA(scPHA) Medium

Controllable -

4HB > 30%

Amorphous PHA(aPHA) Flexible & Tough

Low thermal resistance

Degradation Level

Marine

Soil

Home

Industrial

Brittle

Property

Flexible

- Definition : PHA, Polyhydroxyalkanoate, P3HB4HB

- Chemical structure of CJ PHACT

-

3HB 100%

Crystalline PHA(cPHA) Brittle

High thermal resistance -

4HB 5~15%

Semi-crystalline PHA(scPHA) Medium

Controllable -

4HB > 30%

Amorphous PHA(aPHA) Flexible & Tough

Low thermal resistance

.png)

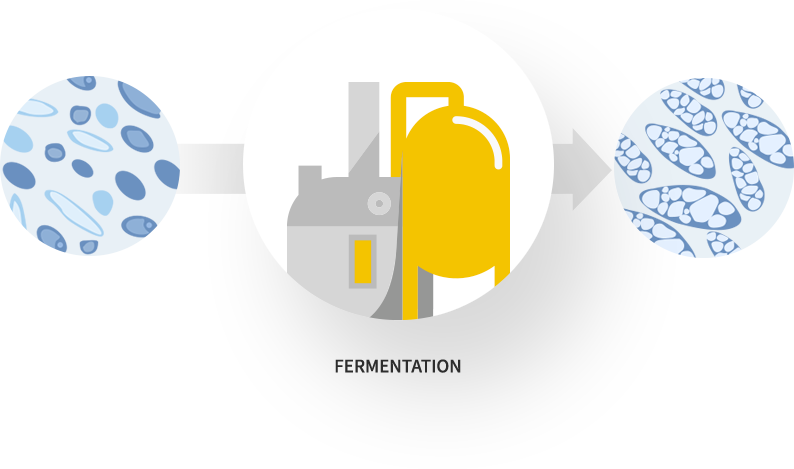

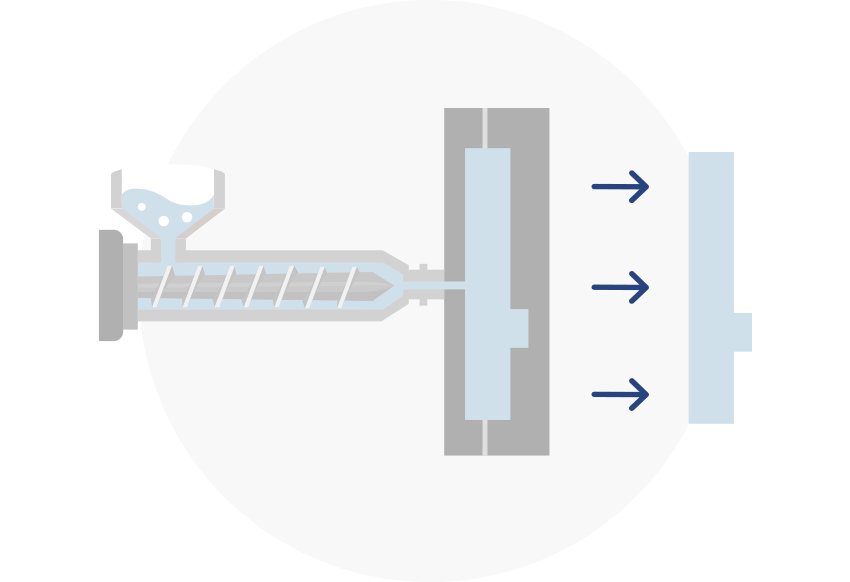

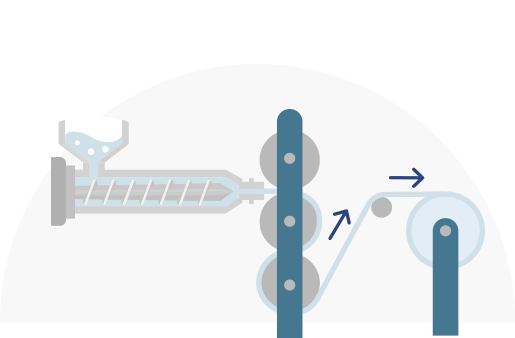

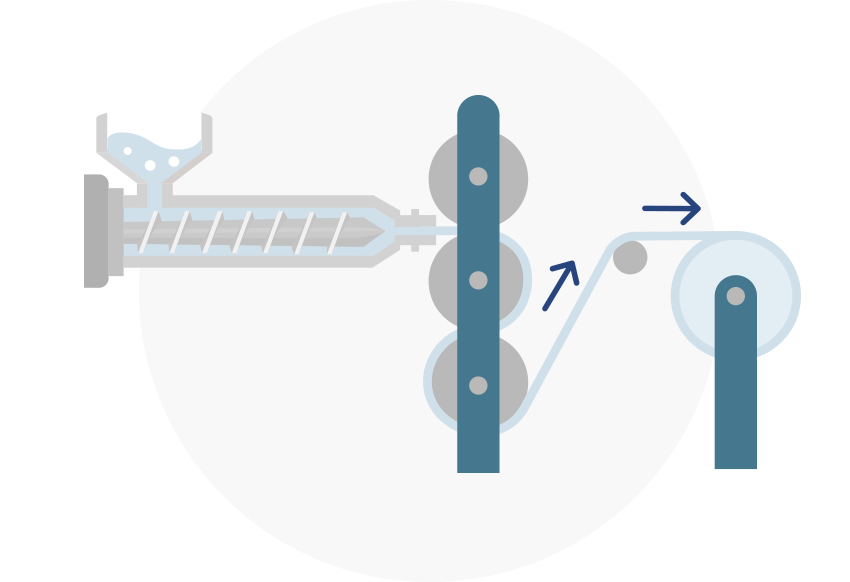

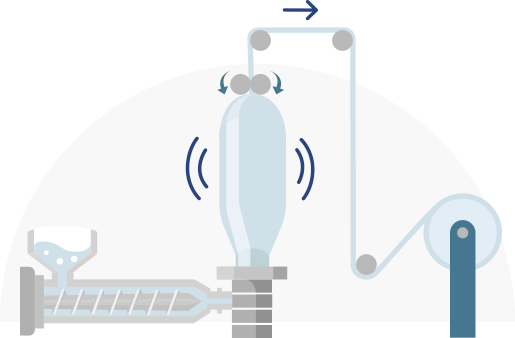

Process Expertise

CJ BIO benefits from decades of experience in developing and scaling up complex Biotech Processes

Raw Materials

From Nature

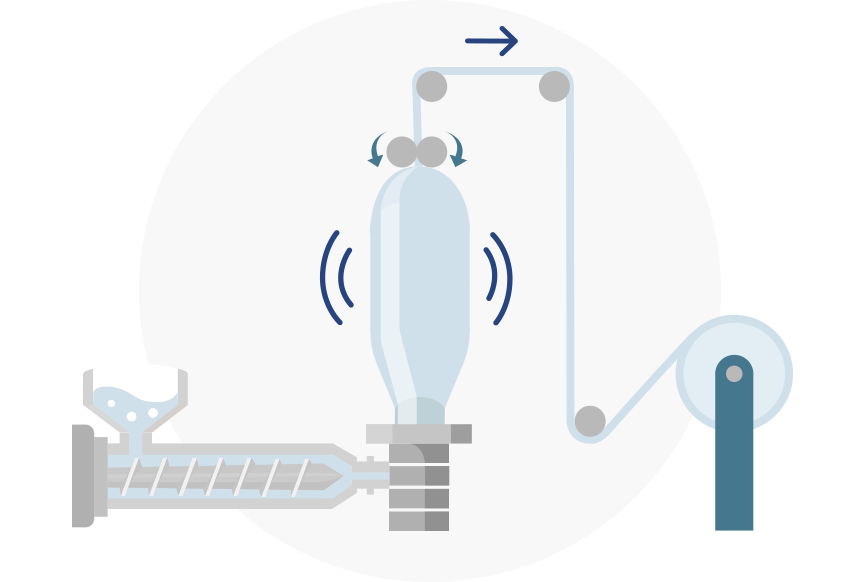

Bio Process

(Strain / Fermentation / Purification)

Large Scale

Production

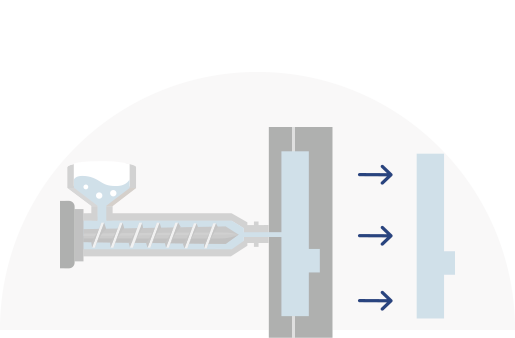

CJ PHACT technology : Applications

-

Injection Molding

Injection Molding -

Film and

Film and

Sheet Extrusion -

Blown Film

Blown Film -

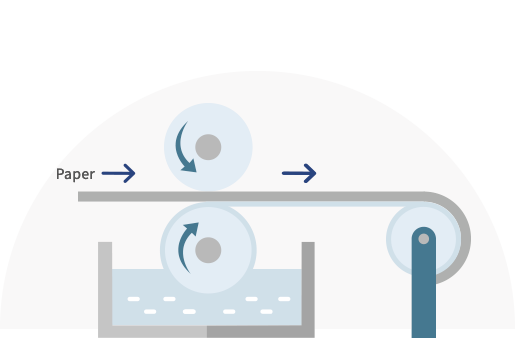

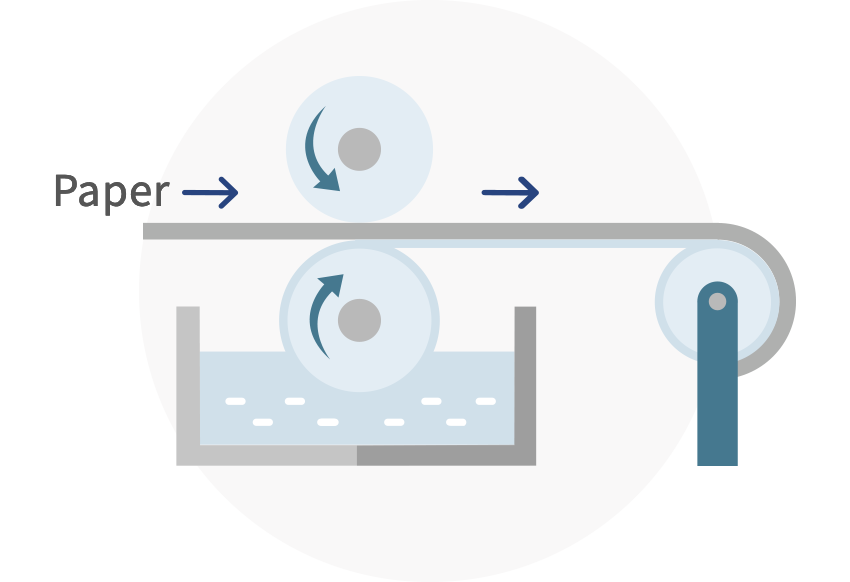

Paper Coating

Paper Coating

-

01. Flexible Packaging

Shopping bag,

Food packaging -

02. Rigid Packaging

Food Container,

Cold Cup -

03. Paper Coating

Cardboard,

Paper Cups Coating -

04. Agriculture

Mulching Film,

Fertilizer Coating -

05. Others

Fishing net,

Cosmetic Container

3D printing filament

-

01. Flexible Packaging Shopping bag,

Food packaging -

02. Rigid Packaging Food Container,

Cold Cup -

03. Paper Coating Cardboard,

Paper Cups Coating -

04. Agriculture Mulching Film,

Fertilizer Coating -

05. Others Fishing net,

Cosmetic Container

3D printing filament

CJ PHACT certifications & registrations

Bio Degradation

Bio Based

Food Contact

PHACT Value Proposition

Enabling circular and sustainable solutions across a range of applications

Biobased

Sugar used as feedstock

Other sources demonstrated.

Fermentation

Microbial engineering enables

high polymer (PHA) accumulation

in microbes.

Recovery

High Purity polymer is recovered and converted

into usable form for downstream processing.

Products and Applications

PHAs can be compounded and

processed using conventional

plastics processing equipment.

Biodegradable

- Soil (Ambient)

- Home Compost

- Industrial Compost

- Fresh Water

- Marine Water

- Anaerobic

Biobased

Sugar used as feedstock

Other sources demonstrated.

Fermentation

Microbial engineering enables

high polymer (PHA) accumulation

in microbes.

Recovery

High Purity polymer is recovered and converted

into usable form for downstream processing.

Products and Applications

PHAs can be compounded and

processed using conventional

plastics processing equipment.

Biodegradable

- Soil (Ambient)

- Home Compost

- Industrial Compost

- Fresh Water

- Marine Water

- Anaerobic