Reevaluating the requirement ratios for broiler growth and yield

2020.07.21

INTRODUCTION

Providing a diet with the proper nutritional value including energy, minerals, amino acids, etc. is critical to recognizing the maximal growth potential and profitability of the modern commercial broiler. Over a 48 year period, the genetic selection of the modern broiler has resulted in over a 400% increase in growth rate, 50% reduction in feed efficiency and an 85% increase in breast filet yield (Zuidhof et al., 2014). The modern broiler has a lower feed intake per unit of body weight gain and the potential for more white meat accretion than the commercial broilers of decades prior. Broilers consuming less feed per unit of gain has led to formulating diets higher in amino acid density in commercial production for improved performance and meat yield (Dozier et al., 2008). This selection process has exerted marked changes in the broilers body composition which in turn influences their nutritional requirements especially regarding amino acids. Similarly, these body compositional changes combined with rearing management strategies such as raising without antibiotics, will in fact influence subsequent amino acid requirements in addition to lysine. A significant amount of research has been conducted on amino acid requirements for which a commercial synthetic product was economically available, such as threonine, however, only recently have significant efforts been made to re-examine changes in amino acid requirements of valine, isoleucine, and arginine.

Historically, valine, isoleucine, and arginine formulated values have typically exceeded minimum ratios recommended by primary breeders in traditional US based diets due to the use of crude protein minimums or the use of only 3 synthetic amino acids. Additionally, increasing any of these ratios could result in significant increase diet cost due to the lack of a commercially available synthetic forms. Therefore, a compromise between performance and diet cost at time must be made by formulating nutritionists. However, with the advancement in fermentation technology, commercially available forms of feed grade valine, arginine, and isoleucine allow for nutritionists to accurately formulate to the requirements of the modern commercial broiler to maximize performance, yield, and profitability.

Threonine

Threonine(Thr) is widely accepted as the 3rd limiting amino acid in broiler diets. Dozier et al., (2015) reported the digestible threonine to lysine ratio to optimize feed efficiency in broilers from 1 to 14 days of age was 69% in diets containing a coccidiostat. Additionally, in multiple studies, Dozier et al., (2016) reported that a digestible threonine to lysine ratio of 68% can optimize growth performance of broiler from 21 to 35 and 35 to 49 days of age although no impact on yield was observed.

The continued global growth of antibiotic free broiler production and increased use of coccidiosis vaccination can result in intestinal damage, increased pathogenic bacteria, intestinal cell turnover and mucin production. Threonine is the major component of intestinal mucin in animals, representing approximately 30% of its total amino acid content (Faure et al., 2002). Due to its importance of maintaining barrier function, mucin is not digested by the normal mechanism with the GIT and thus threonine which is secreted as mucin is eventually lost in the excreta or fermented by cecal microorganisms (Bortoluzzi et al., 2018). Therefore, any situation which induces mucin production would result in increasing the dietary threonine requirement. Induced mucin production associated with intestinal stress or increased bacterial load would shift endogenous amino acid flow and reduce the amount of threonine available for growth. For example, Corzo et al., (2007) demonstrated that the threonine requirement for broilers between 21 and 42 days was 4% higher for broilers reared on built-up vs new litter. Similarly, threonine requirement was reported to increase by 6% during a subclinical intestinal Clostridium infection (Star et al., 2012). Increasing the threonine level during time of intestinal challenge or stress is beneficial on the performance and health status of the animal. Threonine supplementation can reduce cecal pathogenic bacteria such as Escherichia coli and Salmonella and increase Lactobacillus colonies (Chen et al., 2017).

Additionally, threonine supplementation benefits intestinal maturity and integrity by increasing villus height, villus:crypt ratio, goblet cell density, jejunal Ig M and secretory Ig A (Chen et al., 2017). Therefore, nutritionist should consider health status and management conditions and the potential influence on intestinal integrity and endogenous amino acid flow when considering the threonine nutrient specification in the diet. Increasing threonine level should be considered if transitioning off of antibiotics or during periods of known intestinal stress as the increased flow of threonine to the gastrointestinal tract could limit growth potential of the dietary formulation.

Valine

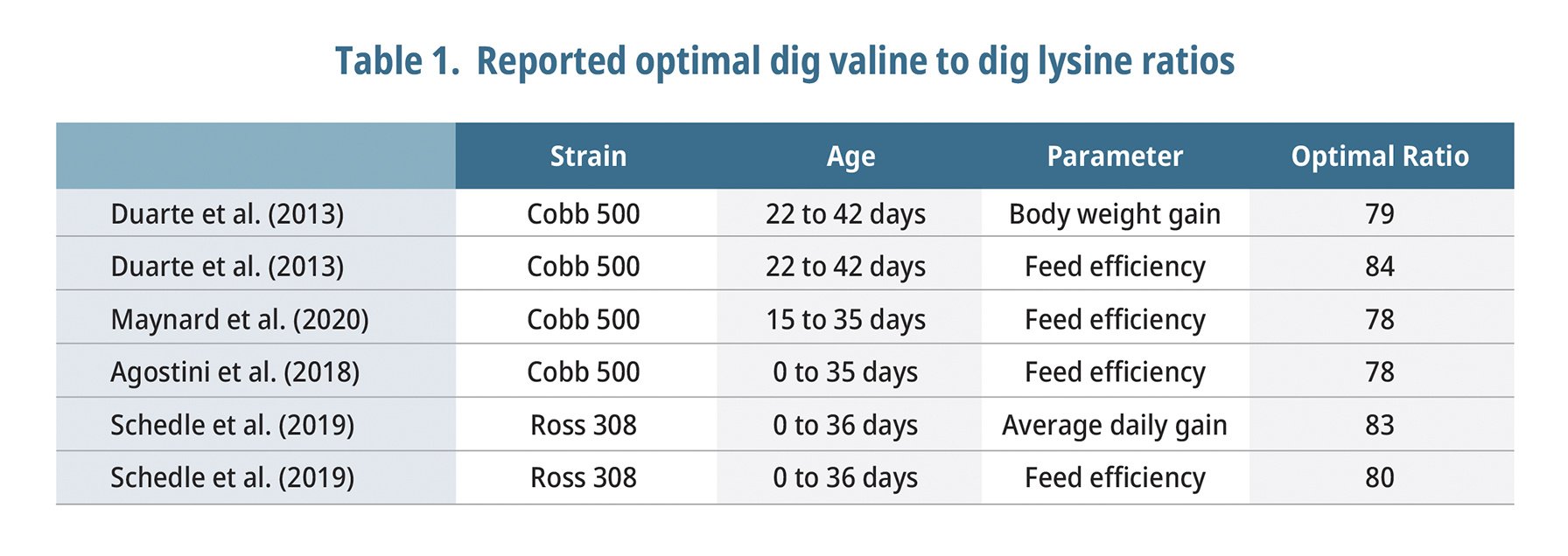

Valine(Val) is recognized as the 4th limiting amino acid in early US poultry diets with the possible exception of diets containing significant amounts of animal protein meal (Maynard et al., 2020). Feed grade L-valine has been commercially available for many years and has recently seen substantial global growth. Having an economically viable source of valine provides nutritional flexibility for producers. Historically, dietary formulations have used valine ratios ranging between 74 and 76% of digestible lysine. However, most recent published data indicate that valine requirements of the modern broiler actually range between 78 and 84% of digestible lysine (Table 1). Kriseldi et al. (2020) recently confirmed the performance advantage of feeding a higher than typical digestible valine ratio by reporting a 50 g increase in d 33 body weight, a 2 point improvement in feed efficiency, and a $0.03 return over feed cost per bird advantage when increasing dietary valine from 74% to 78% of dig lysine in Ross 708 broilers.

As previous discussed, the modern commercial broiler is a rapidly growing, efficient user of natural resources. In order to maintain adequate performance and welfare, proper bone mineralization and feather development is required to ensure skeletal development and skin protection. Valine plays an essential role in both of these vital activities. Valine concentration in the feather increases with age (Fisher et al., 1981), and inadequate dietary valine decreases feather protein and cysteine content. This results in the concave structure of the feathers as they bend away from the body (Farran and Thomas, 1992a). Poor feathering and feather quality results in skin scratches and injuries which can increase carcass condemnations. Additionally, inadequate dietary valine reduces the bone calcium content through decreased mineral deposition by depressing osteoblastic activity. Osteoblasts are responsible for producing the bone matrix of protein and minerals and their reduced activity results in elevated calcium excretion via the kidney (Farran and Thomas, 1992b) as opposed to bone deposition reducing bone strength (Ospina-Rojas et al., 2018). Improper bone development can result in rickets and tibia dyschondroplasia, reducing bird performance and compromising welfare. These observations can be exacerbated when the branched chain amino acid ratios become unbalanced, most likely associated with high levels of dietary leucine. Ingredients such as corn DDGs, peanut meal, and corn gluten meal have excess levels of digestible leucine which may cause imbalances in branched chain ratios within broiler and breeder diets; adjustment of these ratios by the addition of L-valine may benefit feathering, bone density, and performance.

Arginine

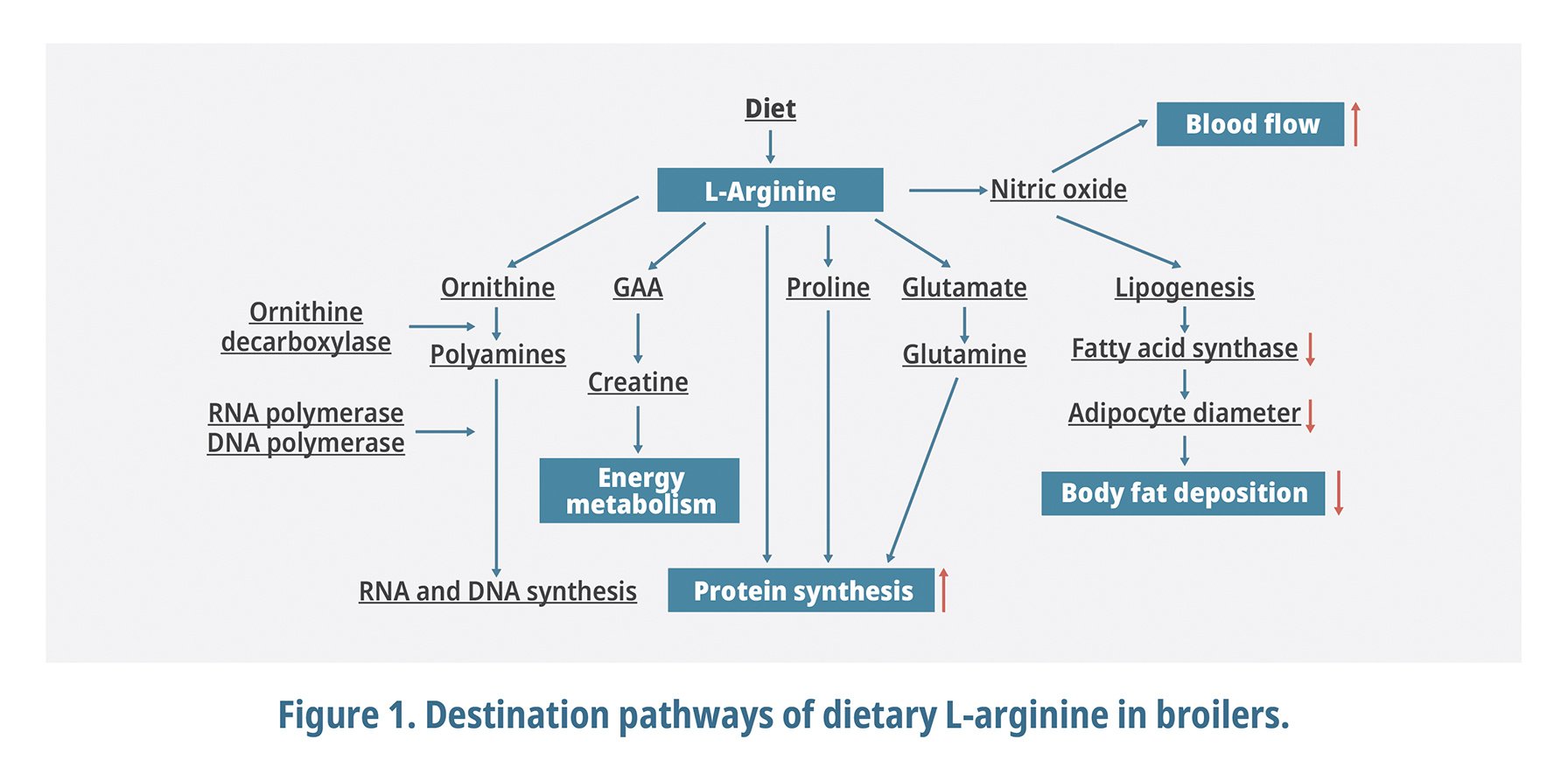

Arginine(Arg) plays a crucial role in numerous metabolic and immunology pathways in poultry (Fig. 1). Arginine is considered an essential amino acid in broilers as they are unable to synthesize endogenous L-arginine because of the lack of a functional urea cycle and therefore, it is essential that the diet provides the optimal level to realize the genetic potential of the modern broiler.

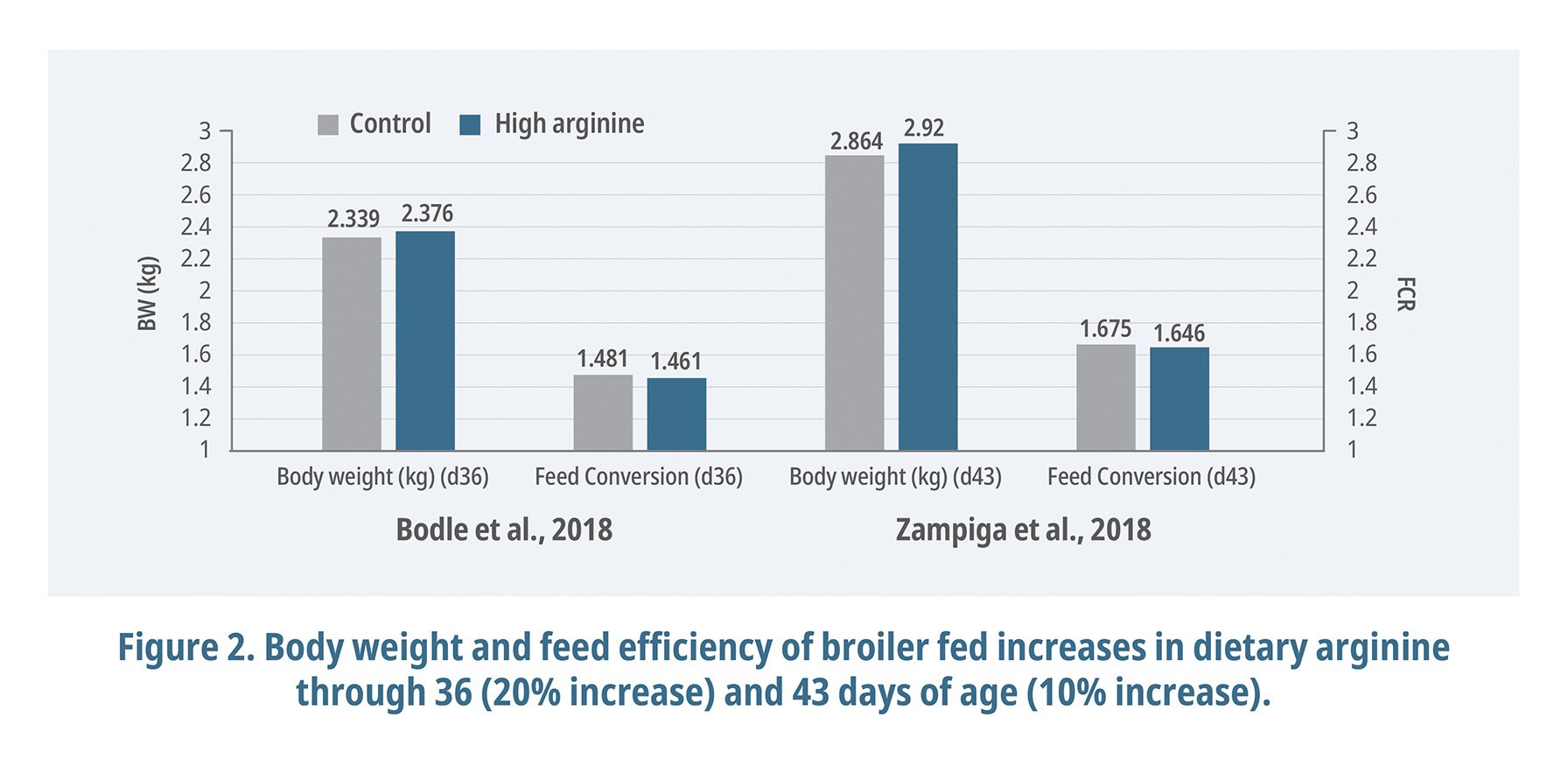

L-arginine has garnered recent interest due to its role in vasodilation and blood flood and its potential benefit on meat quality, and with the recent introduction of feed grade L-arginine multiple published reports have linked elevated levels of arginine with reductions in breast muscle myopathies (Bodle et al., 2018; Zampiga et al., 2019). However, during these investigations, additional benefits on growth performance were observed. Bodle et al. (2018) reported an increase of 40 gram of body weight and 2 point reduction in feed efficiency at 36 days of age with increasing the ratio from 105 to 125. Similarly, Zampiga et al. (2018) observed an increase of 65 g of body weight and a 3 point improvement in feed efficiency with an arginine ratio increase of 10% at 43 days of age (Fig. 2). These results are similar to data reported by Corzo et al. (2012) in which a 114% Arg ratio was found to optimize feed efficiency during the starter phase of production. This optimal ratio matches a recent meta-analysis reported by Dr. Opsina-Rojas of CJ Brazil identifying the optimal ratio for performance to be 114 to 115% of dig Lys (https://en.engormix.com/poultry-industry/articles/optimal-dietary-arginine-levels-t43741.htm).

Isoleucine

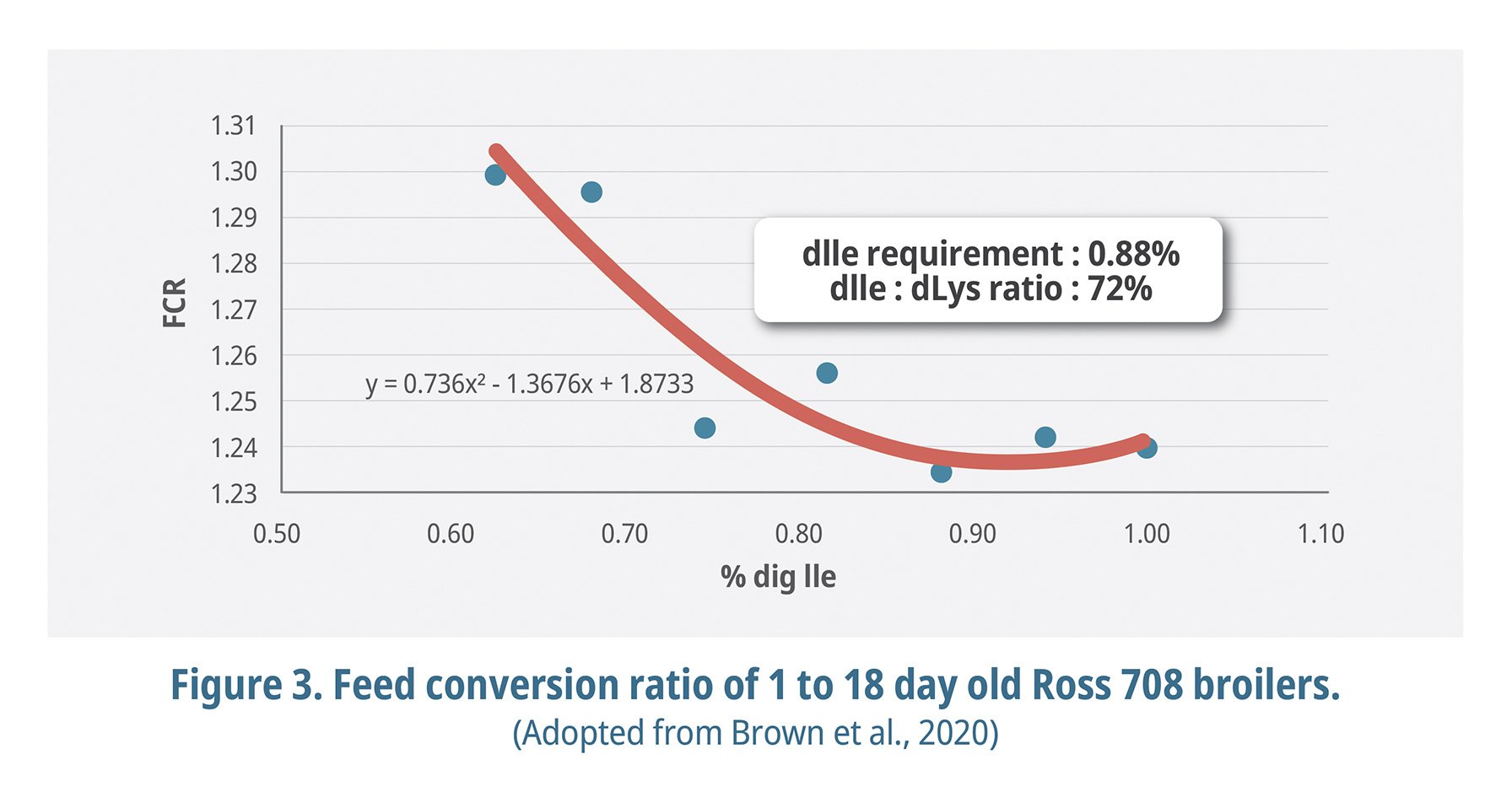

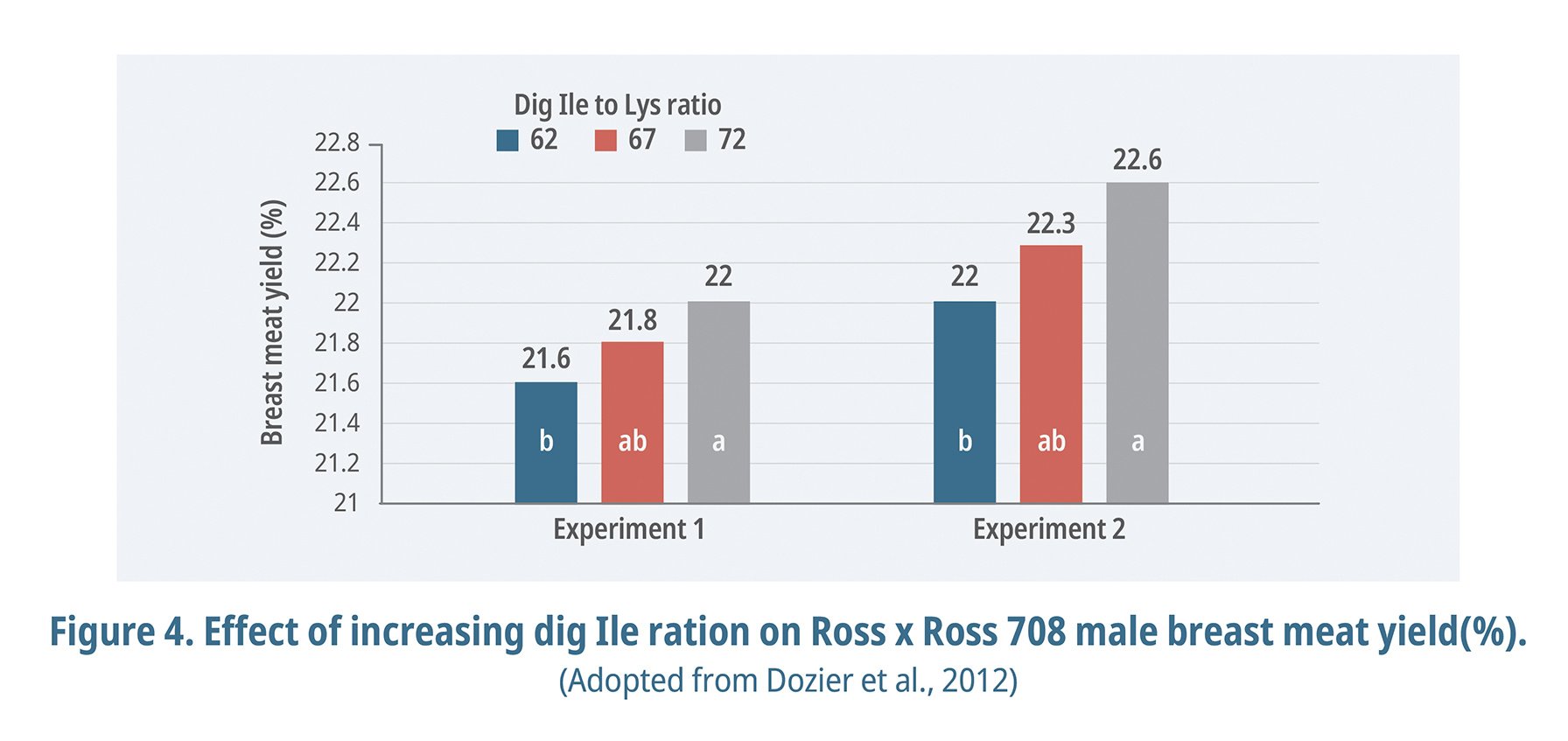

Feed grade L-isoleucine(Ile) has been recently made available on the market place and now available for use in practical broiler diets. Depending on ingredient profile and nutrient specifications, Ile can fall anywhere between the 4th and 6th essential limiting amino acid. As such, in many cases Ile concentration in the diet exceeds the formulation specification. However, in instances of high animal protein and other low Ile containing ingredients, Ile may find itself behind threonine in order of limitation and thus formulation with the proper requirement is essential for optimal growth performance. Recently, Brown et al. (2020) reported the optimal ratio of Ile to Lys in starter Ross 708 broiler males from 1 to 18 days of age was 72% (Fig. 3). Dozier et al. (2012) reported a positive correlation between increasing dig Ile ratio and observed breast meat yield in two experiments. In both experiments, incremental increases in dig Ile ratio correlated with an observed increased in breast meat yield (Fig. 4).

With the current commercial availability of the first seven limiting amino acids in broiler diets, understanding and identifying the proper requirement of each of these amino acid is necessary to maximize broiler performance, yield, and profitability. In a typical corn:soy diet, valine is the 4th limiting amino acid in the vast majority of formulations and thus can protect the other amino acid ratio specifications as they will have exceeded the formulation specification in the diet. However, the expanded use of alternative ingredients in an effort to reduce diet cost results in the switching of the 4th limiting amino acid. For example, high levels of animal protein in the diet will result in an Ile limitation, or high levels of corn DDGs can have a limitation on Arg especially in later phases of production with lower levels of soybean meal. Access to commercially available synthetic forms of each of these amino acids provides nutritionists the ability to capitalize on the benefits of reducing dietary crude protein and potentially reduce diet cost. However, when using the 4th limiting amino acid in a diet, nutritionists must accurately specify the 5th, 6th, and 7th limiting amino acids as each of these will closer approach the minimum specified in the formulation. Therefore, ratios used for these lower amino acids in the past were not as critical as they exceeded the formulation minimum but with the continued growth of producers using the 4th and in some cases the 5th limiting amino acid, incorrect ratios on these lower limiting amino acids may negatively impact performance, yield, and profitability. A significant amount of research in the re-evalaution of these optimal amino acid ratios has recently been conducted and continues in an effort to provide nutritionists to most current information possible when formulating diets. However, the optimal ratios reported seem to be slightly higher than historically used values which may be attributed to the continued selection and changes in body confirmation of the modern commercial broiler. Therefore, with the availability of these feed grade amino acids, nutritionist no longer have to comprise on the amino acid ratio specification in formulation software and can accurate formulate diets to properly meet the nutritional requirements of the broiler and to optimize performance and maximize profitability.