Isoleucine requirements and its role in crude protein reduction in broilers

2020.11.30

INTRODUCTION

After the incorporation of the major five supplementary amino acids namely lysine, methionine, threonine, valine and arginine, the nutritionists are experiencing the pressure point on L-isoleucine to meet its requirements. Generally, L-isoleucine requirement is either being ignored or compromised due to its unavailability commercially in Europe.

Isoleucine has become commercially available recently thus it is important to define its current status in the commercial feeds and to identify the compromises on its requirement in order to achieve the best performance with controlled economics.

Requirements of L-isoleucine

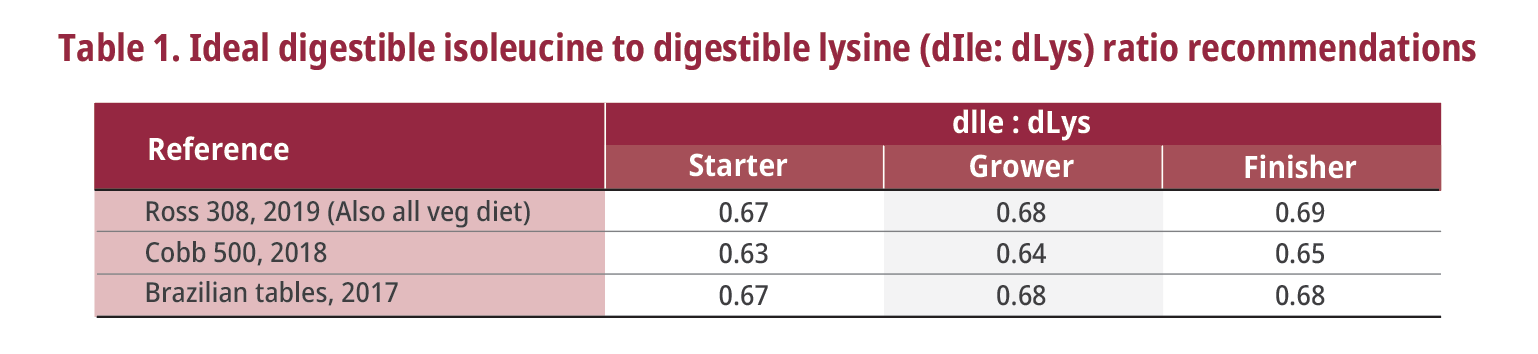

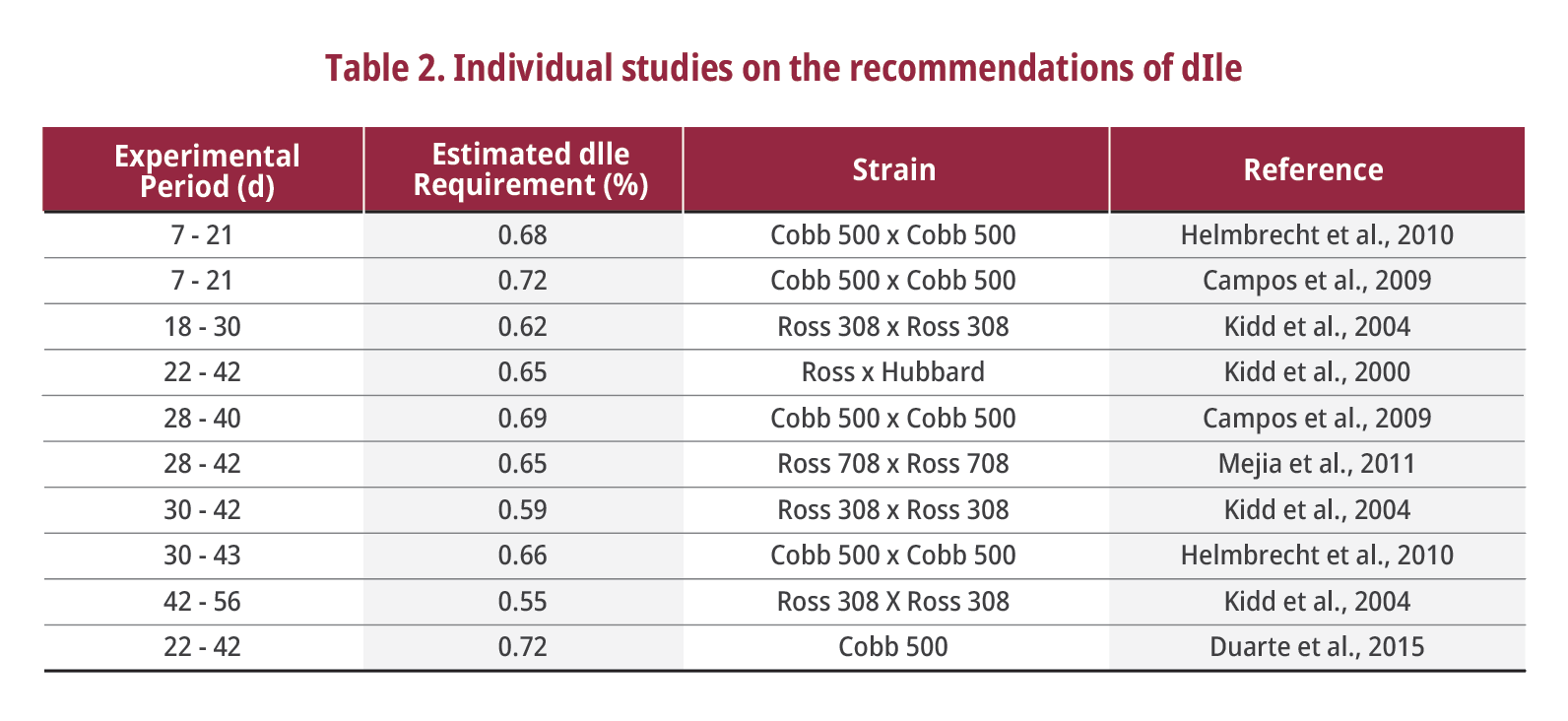

Table 1 and 2 summarize recommendations for the L-isoleucine requirements and the literature studies, respectively

The average trend is showing increase in dIle: dLys with the age period. According to recommended standards the average dIle: dLys for the starter, grower and finisher periods are 0.67, 0.68 and 0.69, respectively. Whereas an individual data available based on different age periods and genetics also shows variable results (Table 2).

Contrary to this, the commercial poultry diets are not meeting the recommended level of L-isoleucine, which is even challenging in low crude protein diets. The estimated Ile to Lys ratio in a commercial diet can vary from 50-66:100. These variations are related to age period, raw material, and the formulation limits or even no limit check on Ile during the formulation.

Balance between branched chain amino acids (BCAAs) in raw materials

Raw materials contain enough of leucine (Leu) as compared to Ile and Valine (Val). Table 3 summarize the ratios between Ile: Lys, Leu: Lys and Val: Lys in commonly used raw materials.

%20in%20raw%20materials.png)

The antagonism of the BCAA is described as early as 1955 (Harper et al., 1995), which can decrease feed intake (Edmonds and Baker, 1987) or cause leg weakness and torn feathers in growing chickens (Farren and Thomas, 1992). Therefore, imbalance between BCAAs should be avoided to get the optimum performance.

Studies are also available which do not show any performance difference due to higher Leu. Waldroup et al., (2002) concluded that the antagonism among or between BCAAs is not likely to reduce the performance of broilers under practical conditions. Erwan et al., (2009) suggested that increasing dietary leucine had no significant effect on feed consumption, weight gain and feed to gain ratio and carcass characteristics, but significantly increased carcass weight up to 9% (P<0.05).

Low crude protein

There are four major reasons for reducing the crude protein (CP) in an intensive farming system:

1. Sparing expensive resources like protein sources

2. Reducing feed cost without losing the animal performance

3. Compliance with the nitrogen excretion regulation

4. Improving the long-term sustainability of the animal production

Until yet, nutritionists were unable to go below a certain level of the CP because of the lack of Ile as a supplementary source. Nowadays, Ile can be very well incorporated in formulating low CP diets without compromising Ile requirements under different raw materials regimes.

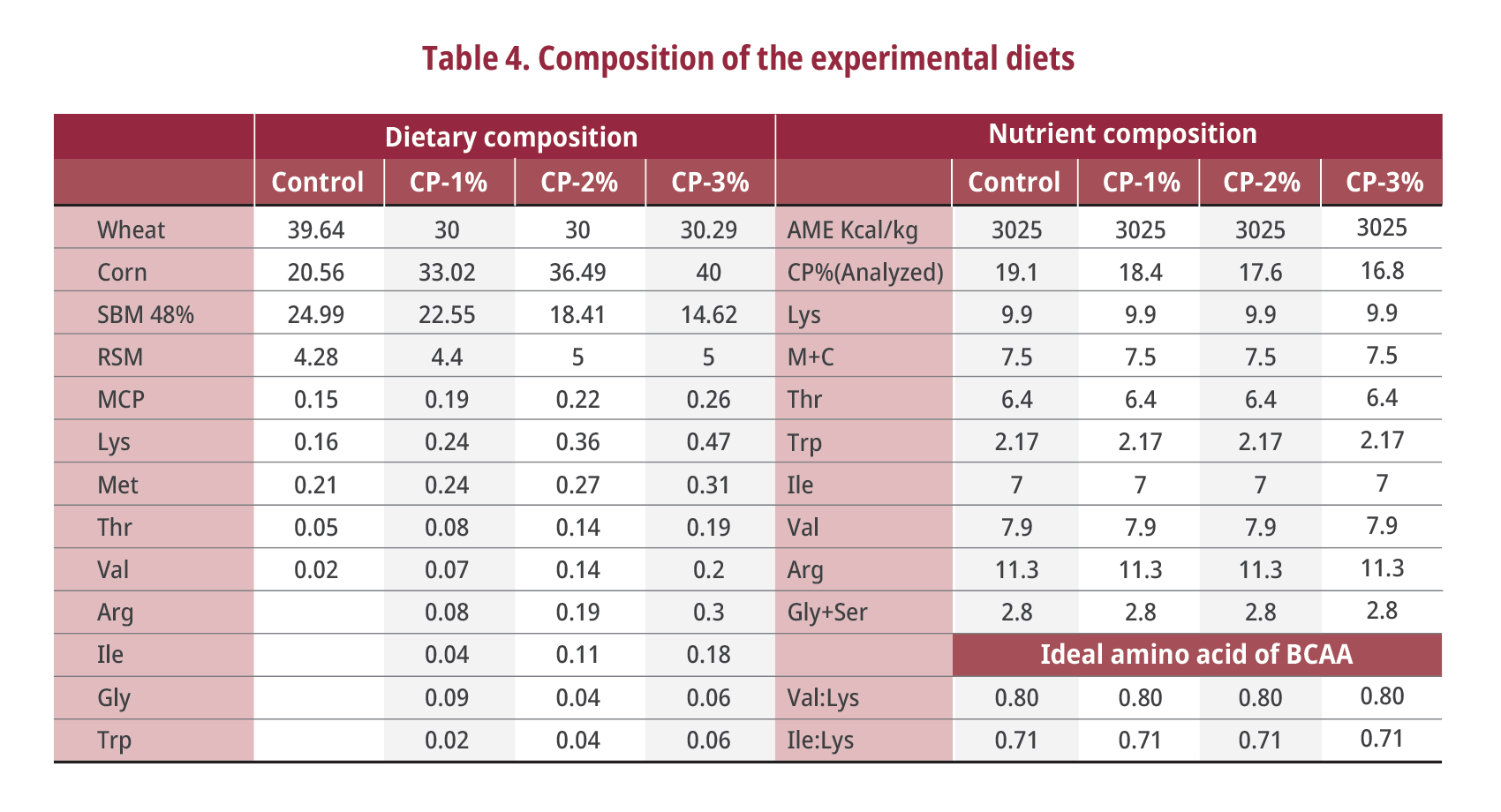

Recently, Van Harn et al., (2019) tested the lowering of CP in grower (CP: 20.8-17.8%) and finisher (CP:19.8-16.8%) diets in broilers. The diet was based on wheat, soybean meal (SBM), rapeseed meal (RSM) and corn, which was fortified with the crystalline amino acids to meet their requirements in low CP treatments (Table 4).

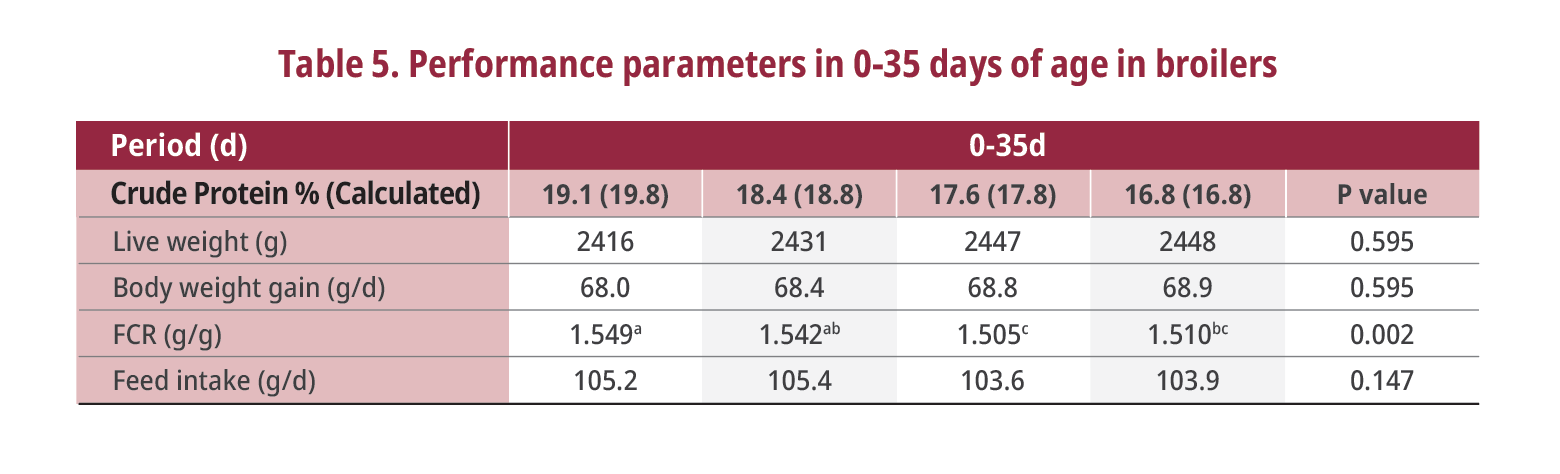

Continuous reduction in CP from 19.1 to 16.8% while keeping the nutrient contents of the diet constant did not impact the performance of the animal (Table 5). Whereas there was a significant improvement in FCR in the diet with 17.6% CP as compared to control diet (CP:19.1%).

Conclusion

L-isoleucine is an essential amino acid in broilers. According to breeder recommendations, the ideal dIle: dLys in broilers are 0.67, 0.68 and 0.69 for starter, grower and finisher periods, respectively. These ratios are a little higher than what is currently being achieved in industrial formulations. However, a constant dIle:dLys ratio of 0.69:1.00 is suggested in all age periods in order to compensate batch to batch variations in protein sources under commercial conditions. In combination with other amino acids, Ile can support formulating an economical feed when incorporated in a low CP diet without losing the animal performance.